In this article, we will discuss the engineering concepts and considerations for a live biotherapeutic products (LBPs) manufacturing facility, along with the challenges associated with a novel facility of this nature. Among the unique challenges that must be addressed in a multiproduct facility manufacturing LBPs is that some species are spore-forming bacteria, which require particularly stringent containment to avoid cross-contamination. To complement these discussions, the article will also provide background information on spore-forming bacteria and their role in LBPs.

Bringing New Products to the Market

The microbiome is vast, and LBPs range from a single strain to a consortium of microorganisms to fecal matter transplants (full spectrum–based LBPs). LBPs create a truly exciting new therapeutic platform with a novel approach to disease treatment and significant potential to improve patient lives. At both DPS Group and Arranta Bio, we are thrilled to be in a position to help advance the field and bring these important new products to the market.

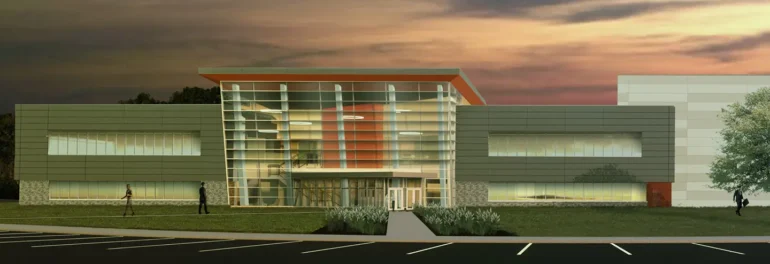

Arranta’s Watertown, Massachusetts facility is configured to allow for expansion to larger-scale production as demand increases. The current maximum fermentation capacity is 2 x 2000 L, with a total of 13 suites across two segregated GMP spaces. A third (future) GMP space, initially intended for warehouse space, has the potential for inclusion of an additional three suites, including the necessary expanded utilities. The Arranta Bio facility design allows for agility in process configurations: incorporating single-use equipment, strategically located utility panels, and a centralized vaporized hydrogen peroxide system (VHP) routed to each room to allow for decontamination as needed.

The Nature of Spore-Forming Bacteria and Their Benefit to Humans

Endospores are widespread in nature. They are found in the soil and water sources and are associated with insects, plants, and animals. Most spore-forming bacteria belong to two genera of the phylum Firmicutes: the aerobic or facultative anaerobic Bacilli and the strictly anaerobic Clostridia, both of which are present in the human gut.

Nonpathogenic spore formers have received growing attention as ingredients in probiotic foods and supplements, and more recently as potential live biotherapeutics for the treatment of a number of diseases and disorders. Evidence suggests that using spore-forming Bacillus and Clostridium strains in the food industry is more effective than employing lactic acid bacteria, because bacterial spores are able to survive passage through the acidic stomach and better withstand processing and storage conditions. In addition, spore-based probiotic products often include bacterial species that humans no longer ingest because fruits and vegetables are routinely washed, peeled, and/or cooked.1

Targeted therapeutic benefits of spore formers have recently become evident. Spores of B. subtilis have also been investigated as drug delivery vehicles. Several strains of Clostridium, meanwhile, have been shown to selectively colonize solid tumors, creating interest in their use for selective tumor targeting and destruction.2 Another recent example of a spore-based microbiome therapeutic is one based on Firmicutes spores for the treatment of ulcerative colitis.3 Other LBPs are being developed based on spore-forming Clostridiumbacteria for targeted delivery to the colon.

Manufacturing Challenges with LBPs and Spore Formers

Since LBP manufacturing processes typically include some combination of upstream fermentation, harvest separation, downstream purification, lyophilization, solids milling, and capsule filling, a suitable contract manufacturer must be knowledgeable and skilled with this specialized GMP equipment.

Additional capabilities for maintaining anerobic/low-moisture conditions during the entire production process, from upstream fermentation through encapsulation, are also needed. The process must be designed and controlled to maintain the viability of the live bacteria, not only in upstream operations, but also throughout the downstream processing.

Approximately 10–20% of the bacterial strains being developed as LBPs are spore-forming bacteria. As these therapeutic candidates advance through the clinic, the need for manufacturing facilities designed to safely handle spore formers has increased. This presents a challenge for developers of spore-forming LBPs, as most contract manufacturers do not produce spore-forming bacteria in their facilities due to the challenges associated with eradication of this particular type of microorganism. The endospore can withstand harsh environments and is far more difficult to kill then vegetative bacteria, which presents a challenge for cleaning and disinfection. Working with spore formers is particularly challenging in facilities with re-usable product contact surfaces and equipment, such as stainless-steel fermenters. Not only are spore-forming organisms harder to kill with traditional clean-in-place (CIP) and sterilization-in-place (SIP) cycles for cleaning of a bioreactor, but the ability to validate the cleaning and sterilization process is that much more difficult, because the spore-forming organism is an anaerobe, which presents recovery challenges.

The U.S. FDA has generated the guidance Manufacturing Biological Intermediates and Biological Drug Substances Using Spore-Forming Microorganisms to define the minimum set of requirements to enable a multi-product facility to handle these types of microorganisms. Additionally, using single-use product contact surfaces and closed processing, which is standard practice in biologics manufacturing, throughout the process is extremely important for product quality.

Architect/Engineering Firm Partner Selection and Facility Design Process

Designing and building a facility that incorporates a complex manufacturing process with unique regulatory requirements requires aligning with an architecture and engineering firm that brings knowledge and experience to the project. Selecting a firm that specializes in the life sciences is helpful but finding one that is specifically experienced in novel therapies manufacturing is ideal.

For new facilities involving next-generation products and newer technologies, the challenges can be even greater. In these cases, a collaborative approach becomes even more important. The process begins by holding workshops with the client to learn the process, identify all the key features that will impact the design, and achieve consensus on the user requirements of the facility.

It is critical to engage a team of architects and engineers that have experience in working with the segregation and process equipment needs of novel therapeutic manufacturing facilities. Material and personnel flows, as well as air-handling solutions, are specifically designed to address working with LBPs. Well-conceived flow diagrams that depict these movements are essential to developing a design that limits the risk of contamination associated with spore formers.

As an ISO 9000 company with more than 45 years of experience, DPS has developed a highly structured approach to design projects, including those for LBP facilities. DPS has experience with clients at all levels of capital project execution maturity, phases in company growth and product development, and project driver motivations. DPS is also experienced in designing novel therapeutic manufacturing facilities for a variety of technologies, leading to a thorough understanding of the specific design and regulatory differences and requirements.

Early collaboration, process needs identification, governing systems philosophy creation, and facility operational requirements (FOR) development are key to the success of any biotech buildout project. This foundation will drive the decisions of the later phases of design.

All design projects have design reviews at key milestones for deliverables. These reviews check cross-discipline alignment and adherence to the project’s governing philosophies. They are also a time to perform risk assessmentsn such as process hazards analysis (PHA). With LBPs, these design reviews are also a point to conduct a contamination risk assessment. Evaluating the risk and determining a mitigation to any identified high-risk item builds a safety factor into the design.

Designing a safe manufacturing facility for spore-forming LBPs offers a unique engineering challenge. By partnering with an experienced engineering firm, taking a methodical approach to the design, and assessing risk at each phase, a successful and contamination-free LBP manufacturing plant is achievable.

About the Contributors

DPS is a global architectural engineering, consulting, and project management company, serving high-tech industries around the world. DPS designs biopharmaceutical facilities from the first generation of recombinant proteins through monoclonal antibodies (mAbs) and modern-day novel therapies, such as gene and cell therapy, viral vectors, RNA, oligonucleotides, microbiome, and exosome. DPS’s teams also embrace technology advances, such as continuous manufacturing (perfusion and continuous downstream processing), advanced process analytical technology, improved single-use systems, and modular and podular designs.

Arranta Bio is a visionary contract development and manufacturing organization (CDMO) that strategically partners with leading microbiome innovators to provide manufacturing, scientific, and regulatory expertise. Arranta’s dedicated team, state-of-the-art facilities, and unparalleled resources are crucial for advancing live biotherapeutic products (LBP) from development to commercial launch. Arranta Bio has experience with aerobic, anaerobic, spore-forming, and genetically modified organisms for both single-strain and consortium products. Built specifically for LBP drug substance and drug product manufacturing, Arranta’s facilities continue to expand capacity across multiple sites in order to meet the evolving demands of their clients and partners.

References

- “Spore-based probiotics provide bacteria species we rarely ingest anymore, due to washing, peeling and cooking our vegetables.” Emerson Ecologics. 16 Aug. 2019. Web.

- Umer, Brittany, David Good, Jozef Anné, Wei Duan and Ming Q. Wei. “Clostridial Spores for Cancer Therapy: Targeting Solid Tumour Microenvironment.” Journal of Toxicology. 2012: 862764 (2012).

- Henn, Matthew R. et al. “A Phase 1b safety study of SER-287, a spore-based microbiome therapeutic, for active mild to moderate ulcerative colitis.” Gastroenterology. 4 Aug. 2020. Web.

- Tetz, George and Victor Tetz. “Introducing the sporobiota and sporobiome,” Gut Pathogens 9: 38 (2017).

- Guidance for Industry Manufacturing Biological Intermediates and Biological Drug Substances Using Spore-Forming Microorganisms.S. Food and Drug Administration. 2007. Web.

Originally published on PharmasAlmanac.com on June 25, 2021.